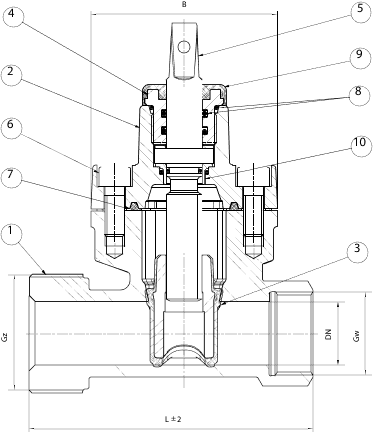

Foundry

Anchor SB3P

Anchor SB3M

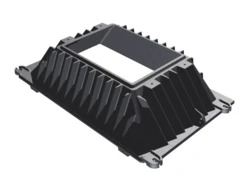

Grating

Mining yoke 2

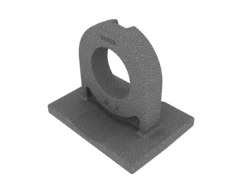

Bracket

Element of forklift

Mining yoke

Pulley

Ingots mortar

Bearing

Band

Swingarm

Fireplace insert

Element of cylinder engine bracket

Frame of the tractor mower 2

-

Cerficate ISO 9001:2015

Cerficate ISO 9001:2015

Cerficate ISO 9001:2015 -

ISO 14001:2015 Certificates

ISO 14001:2015 Certificates

ISO 14001:2015 Certificates -

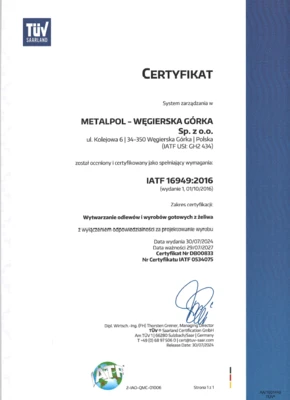

IATF 16949:2016 Certificate

IATF 16949:2016 Certificate

IATF 16949:2016 Certificate -

REACH Declaration

REACH Declaration

REACH Declaration

Contact us