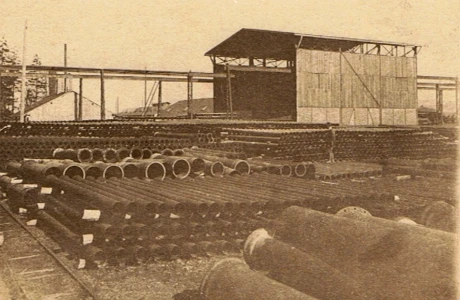

METALPOL is one of the oldest plants in the metallurgical sector in Poland; steelworks - the predecessor of today's foundry was founded in 1838.

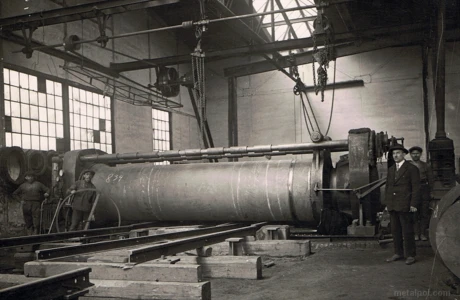

After some time the mill gave place to iron foundry and fittings factory, which, despite the wars, the ups and downs, continually developed and was in the period before and after the war leading manufacturer of fittings in Poland.

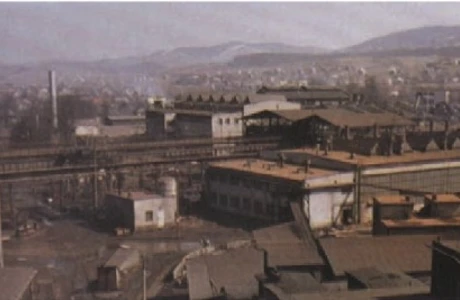

In the late 1990s, changes in political and economic system in Poland, became the cause of the difficulty in a factory getting used to new reality. As a consequence, in 2000, the plant became a part of French casting group CF2M and changed its name to METALPOL.

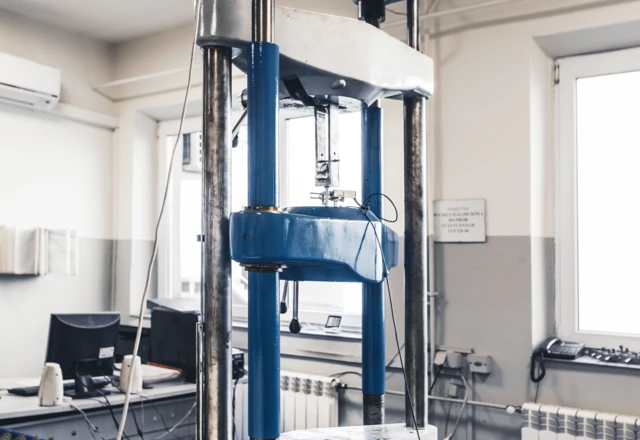

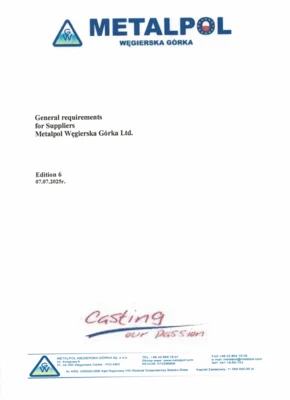

In subsequent years, the factory, using the help and experience of specialists of the French group, has been thoroughly modernized and reconfigured to meet the standards of Western Europe and respond to customer demands.

In 2010 METALPOL, under the management buyout, became back the company with entirely Polish capital.

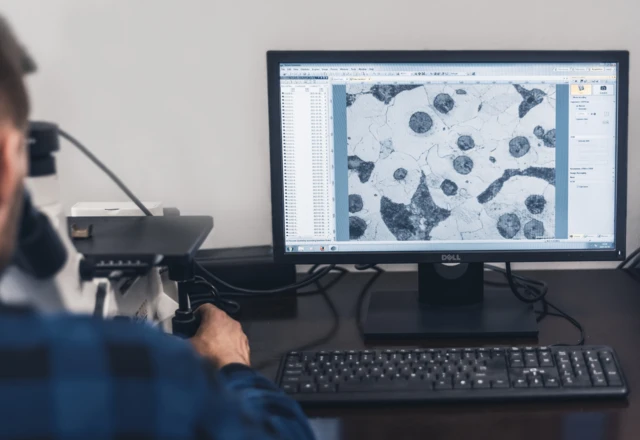

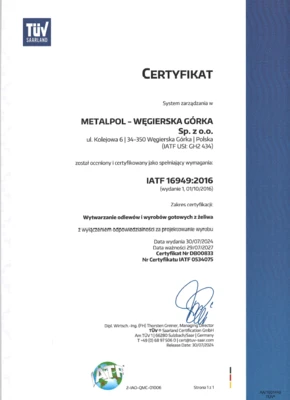

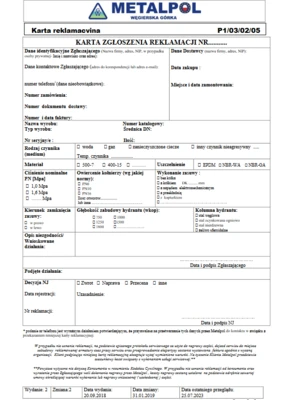

METALPOL is a company that wants to develop, gain new markets and meet the ever increasing demands of customers, paying attention to quality management systems as a vector of development.

The Company as early as in 2000 implemented a quality management system ISO 9001, and in 2005 the quality system compliant with the ISO / TS

METALPOL, at the same time, ensure that production takes place in conditions that guarantee the protection of the environment, which in 2004 was confirmed by environmental management certificate ISO 14001

METALPOL currently employs about 250 skilled workers with years of experience, equipped with the latest tools and IT systems in the field of technology and an integrated manufacturing management and finance system.

The company continues to grow each year and devotes a significant amount of investment in the development of the Company and its employees.

METALPOL has headquarters in Węgierska Górka Kolejowa str. 6.